The team led by Ding Ma and Meng Wang at the College of Chemistry and Molecular Engineering, Peking University has developed a catalytic method to co-upcycle two plastic wastes with similar density, polyvinyl chloride(PVC) and polyethylene terephthalate (PET), to valuable products. In this work, hydrogen chloride (HCl) generated from dehydrochlorination of PVC was stored in ionic liquids for the depolymerization of PET. This process utilizes chlorine resources, which were previously considered as a troublesome pollution in waste plastics. At the same time, two important chemicals, ethylene dichloride (EDC) and terephthalic acid (TPA), were produced with high yields.

Plastic is an indispensable material with a global production reaching nearly 400 million tons in 2020. In the past, the post-consumer plastics were considered as garbage. It is estimated that more than 80% of waste plastics are directly discarded, landfilled or incinerated after use, without effective recycling, resulting in serious environmental pollution and resource waste. Recentresearch on chemical recycling of plastics mainly focuses on a single type of pure plastic. However, one of the greatest difficulties of plastic recycling is the high cost of classification and separation of plastic wastes. The simultaneous transformation of plastic mixtures through reactions between various polymers is a sustainable solution to address this problem, while relevant research remains underexplored.

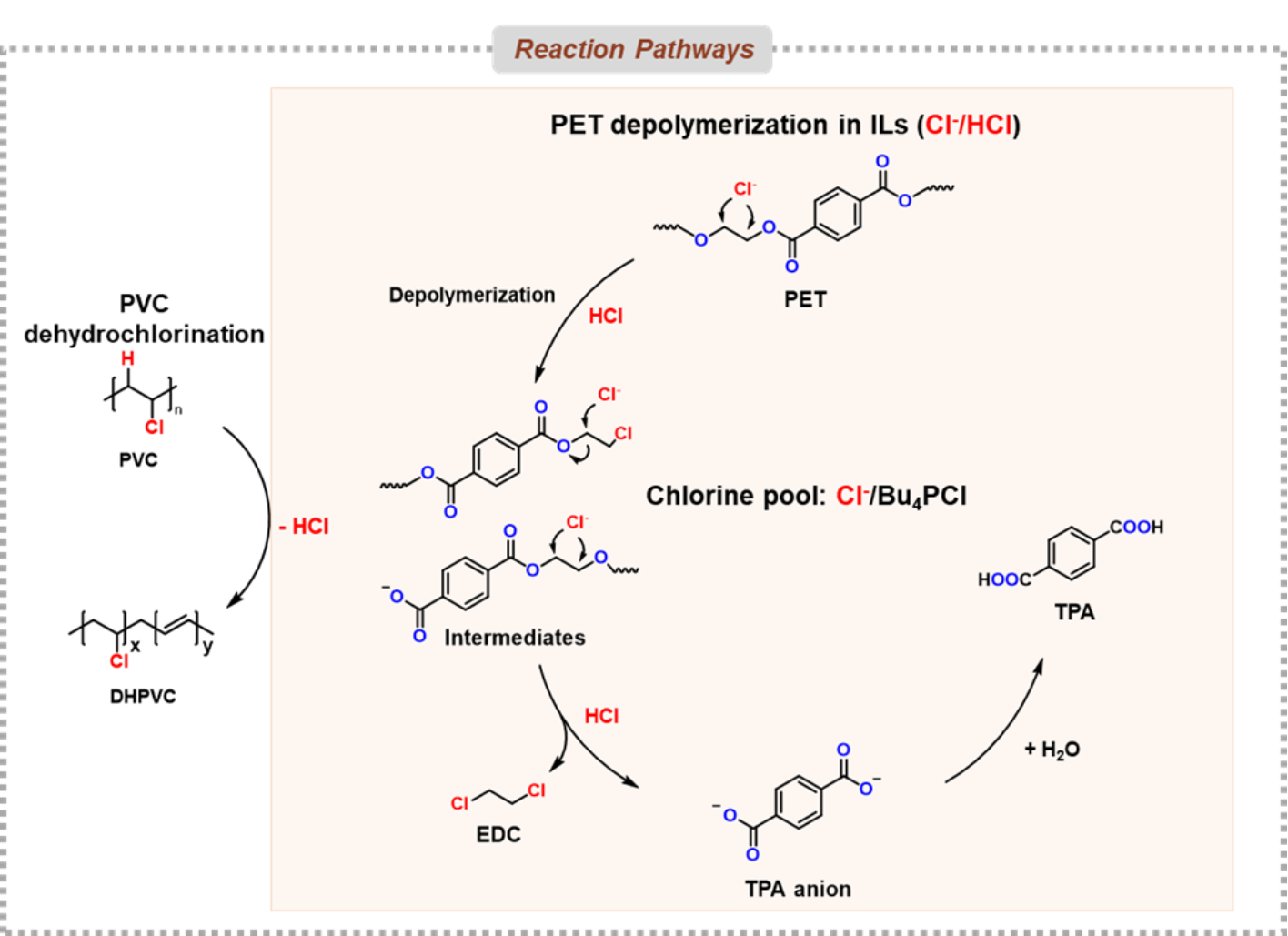

In this work, ionic liquids are used as solvent for co-upcycling reaction, catalyst for dehydrochlorination process of PVC and media for HCl storage. After experimental screening, it is found that Bu4PCl ionic liquid has good catalytic performance for dehydrochlorination and high HCl storage content. PET and PVC co-upcycling is performed at 230 °C in Bu4PCl, resulting high yield of TPA (98%) and EDC (94%). The proposed reaction pathway is shown in Fig. 1.

Fig.1 Proposed reaction pathways of co-upcycling of PET and PVC in ionic liquids.

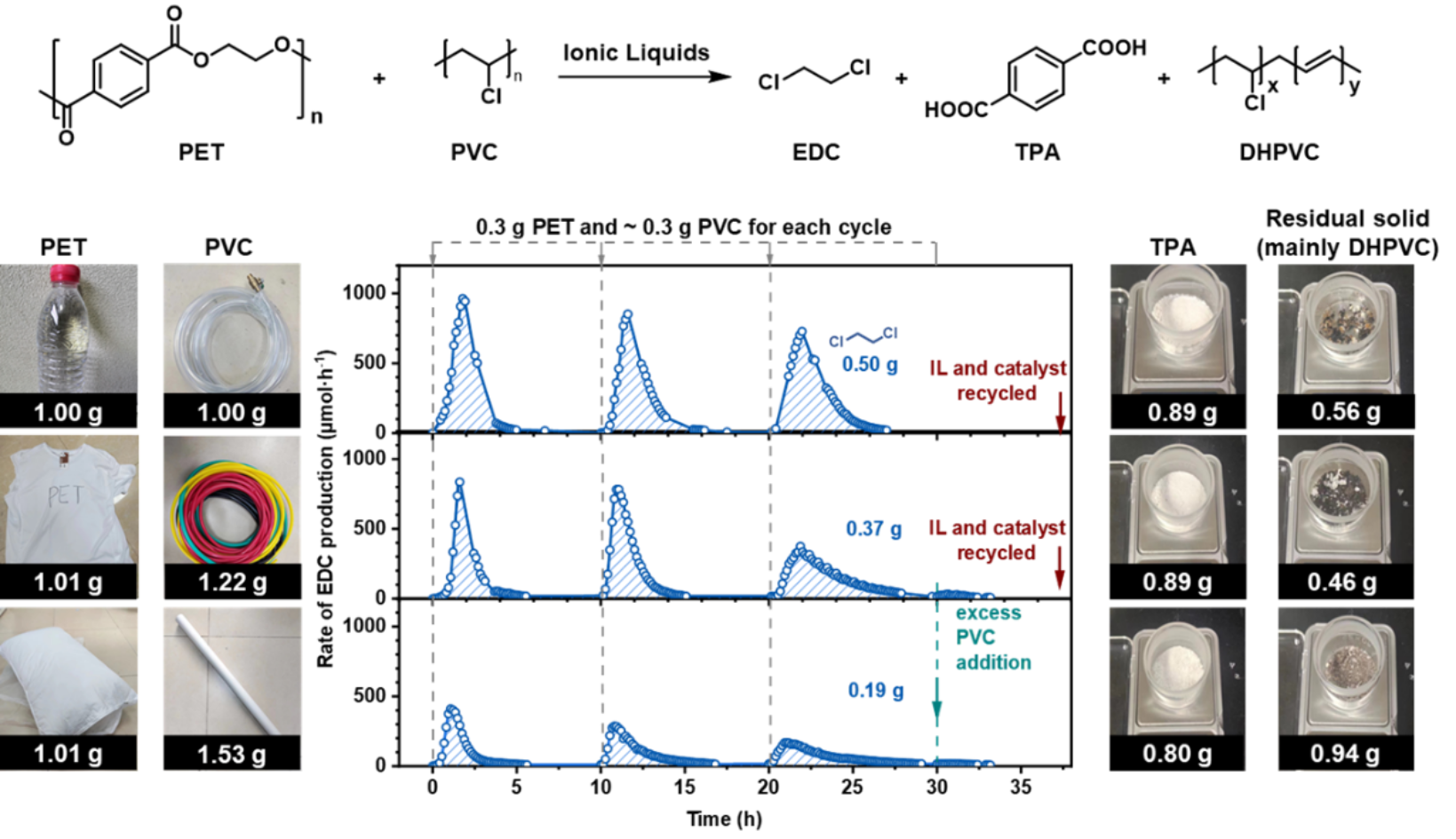

To explore the applicability of the catalytic system, three groups of real-life plastic products (bottles, cloth, hose, etc.) made of PET and PVC are tested. In this case, ionic liquid and catalyst are recycled and reused. Despite slight decreases in the generation of EDC, TPA and EDC can be produced effectively in all three experiments (Fig. 2), which indicates that this co-upcycling system has good stability, tolerance and compatibility.

Fig.2 Co-upcycling of real-life plastic products made of PET and PVC.

This work is titled “Co-upcycling of polyvinyl chloride and polyesters” and is recently published in Nature Sustainability. Ruochen Cao, Mei-Qi Zhang and Yuchen Jiao are the co-first authors of this paper. Prof. Ding Ma and Assoc. Prof. Meng Wang, from Peking University are the co-corresponding authors. This work received financial support from the Natural Science Foundation of China, National Petroleum Corporation-Peking University Strategic Cooperation Project of Fundamental Research, Beijing National Laboratory for Molecular Sciences and the New Cornerstone Science Foundation.

Original link for the paper:

https://www.nature.com/articles/s41893-023-01234-1